Europe Steelpress’s cold forming machinery fleet consists of high-tech equipment. It includes mechanical presses with a tonnage ranging from 60 to 500 tonnes, work tables up to 2,800 millimetres and automation of both electronic coil feeders, with a maximum width of 1,000 millimetres, and electronic transfer units. Thanks to experience gained over the years, Europe Steelpress can handle projects already underway, taking charge of the customer’s existing moulds. Likewise, we manage new orders optimally, supporting the customer in the planning phase of new equipment and production start-up.

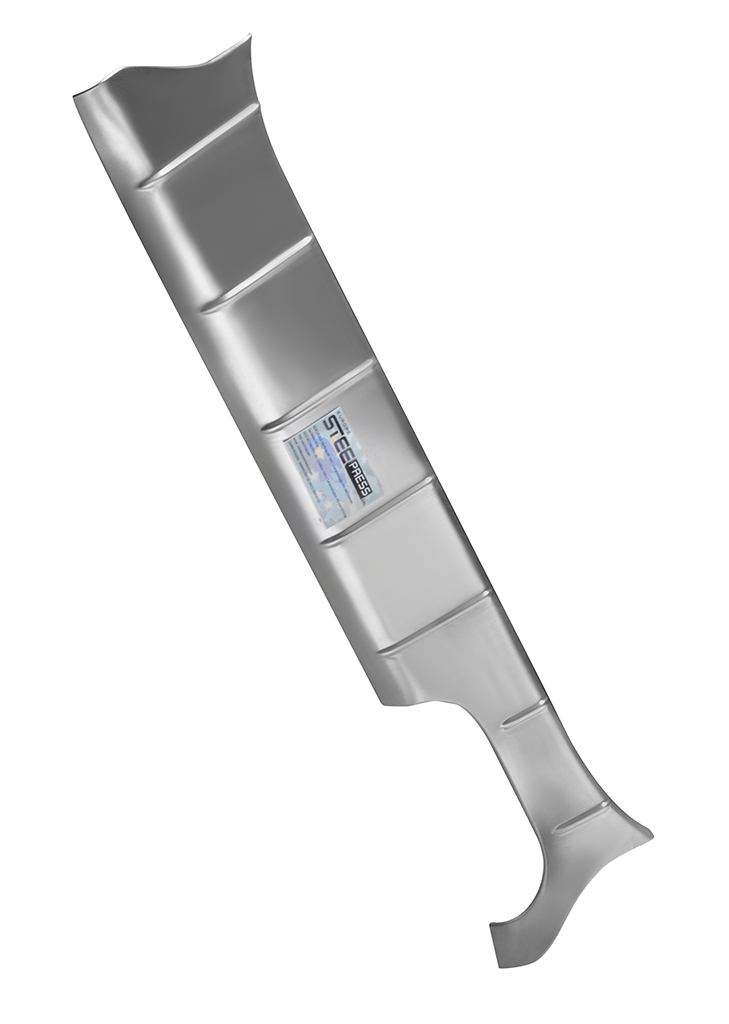

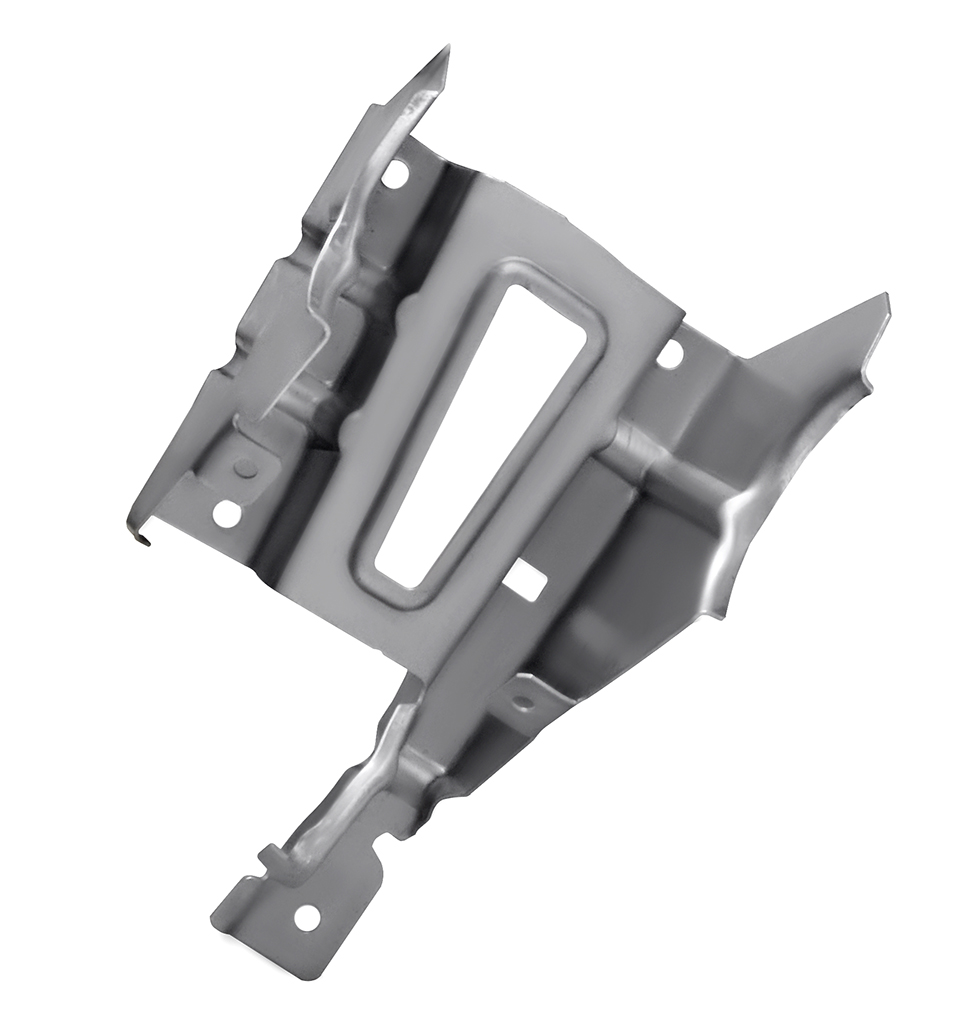

Cold forming and blanking

Customisation according to requirements

Cold forming is a process used and demanded in many sectors, always with different characteristics: for this reason, the entire forming operation is carried out according to the customer’s individual and specific requests.

We use different lines: for large volumes, we usually use automated forming lines, while for precision work we use manual systems. In each case, we guarantee the highest standards of quality whatever the type of processing.

High performance machinery

High technology to guarantee the customer a job tailored to his requirements

Our skills

Standard or on demand

Thanks to our team and our opening towards technological innovation, we have become a trusted partner in the field of metalworking for all industrial sectors. Our technical department is always at your disposal for every needs, or for standard products to be delivered at short notice.

Request more information